frp grating clips

Description

Safety Precautions

When cutting frp Grating , please always wear safety goggles to protect your eyes and a dust mask to reduce dust inhalation. Also wear gloves and a shop coat with neck and sleeves taped to prevent skin irritation. Work in a well-lighted and ventilated area.

Cutting Products

Depending on the amount (lineal feet) of fiberglass grating to be cut, a variety of shop tools can be used. For the best results, use a heavy-duty rotary saw with a masonry, carbide or diamond coated blade. Firm support of the panels will prevent shifting. Turning the panel bottom-side-up gives a smooth surface for the saw to ride on and reduces chipping. Be sure to allow for the blade kerf when measuring.

Grinding

All cut edges should be ground smooth. Use a coarse gritted, open coated (resin) grinding disk.

Finishing

All cut surfaces should be coated with resin to prevent corrosion of glass fibers. A coating of a two-part resin system or comparable to the resin used in the manufacture of the fiberglass grating should be used to maintain corrosion resistance.

Installation

Installation recommendation-whenever possible, provided for a minimum of 1-1/2”(40mm) bearing support at all grating support points. Hold down clips should be used at the rate of one clip for every 6 square feet(0.56square meters) of grating minimum,or at least 4 clips for any square or rectangular piece, or at least 3 for a triangular piece

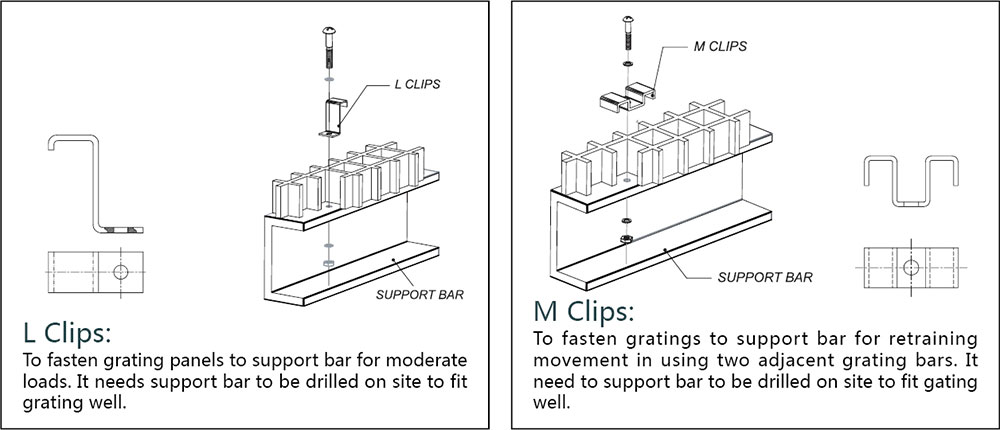

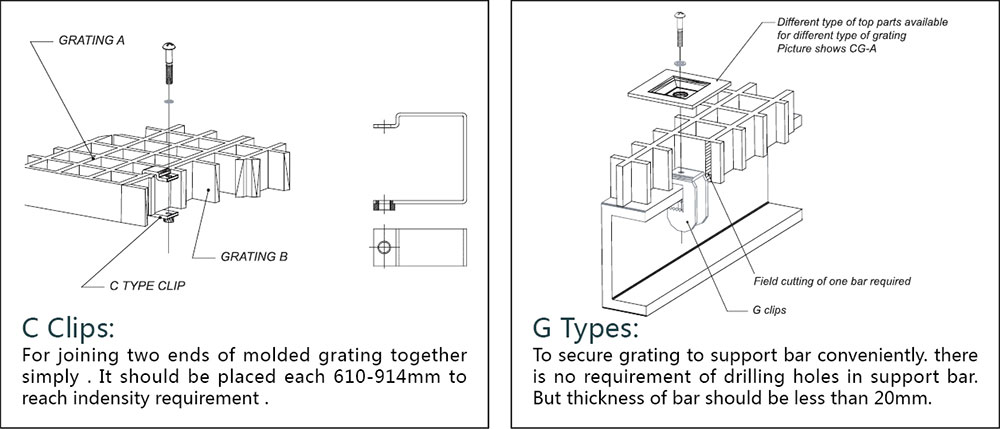

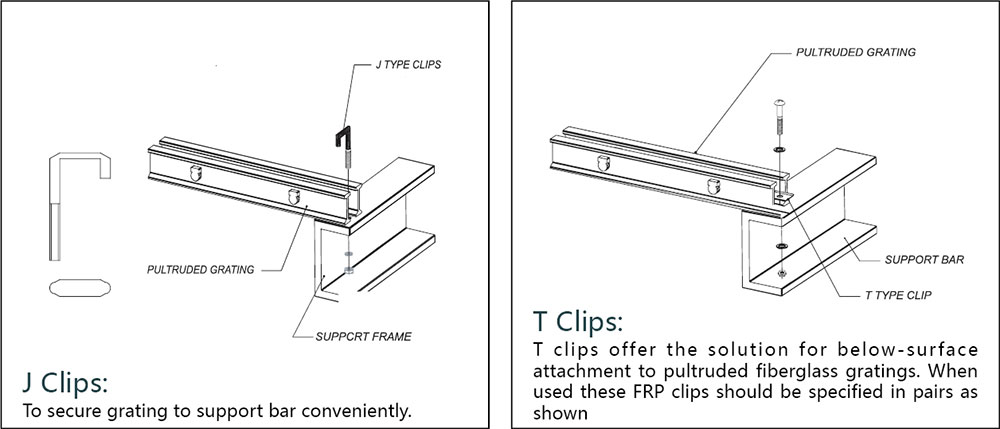

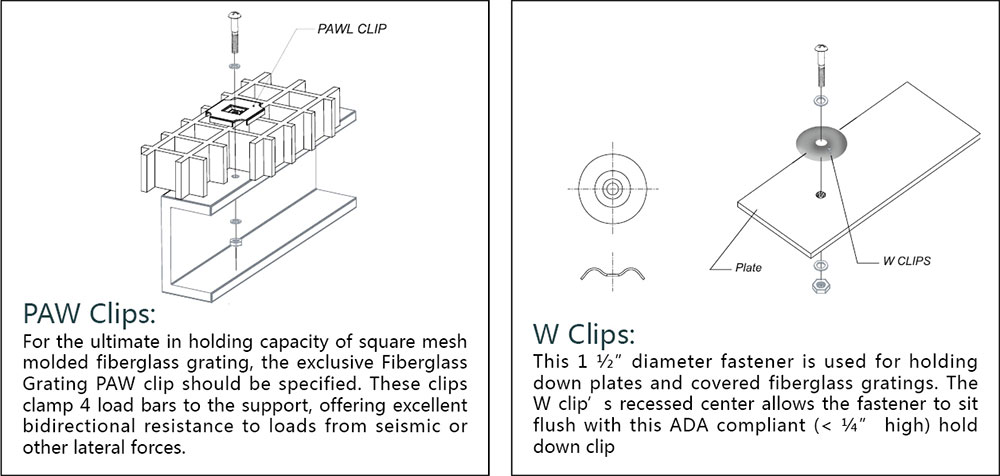

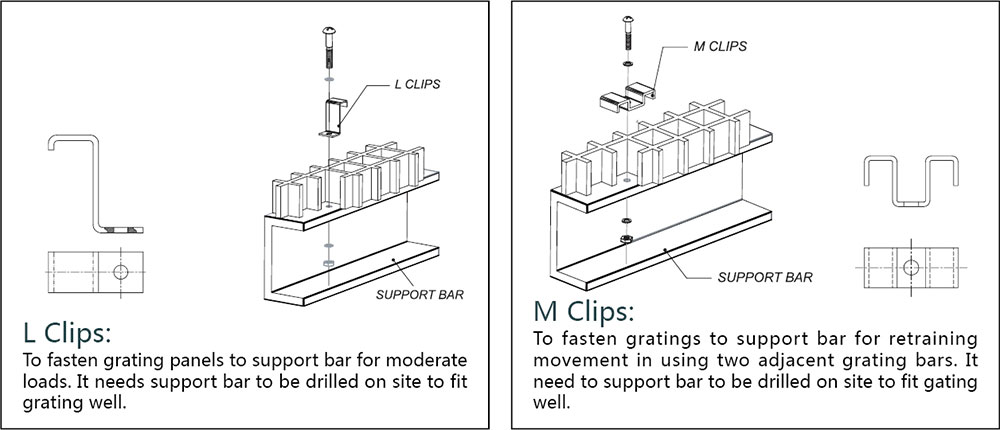

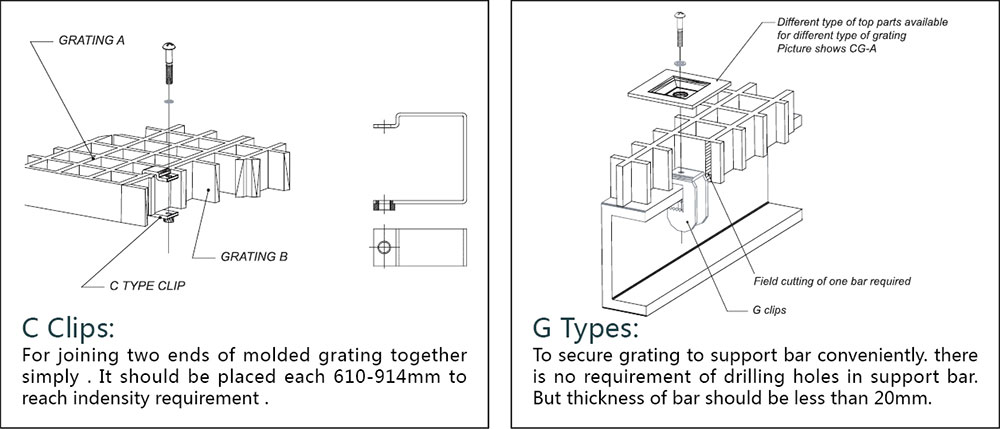

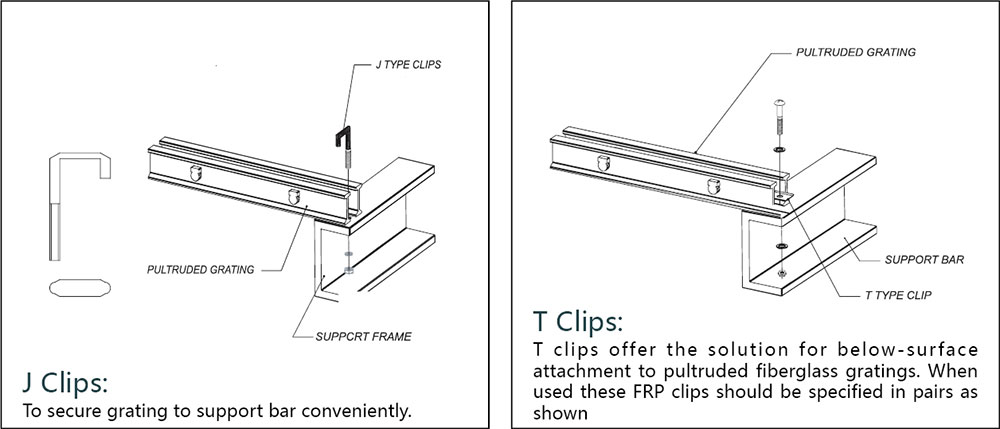

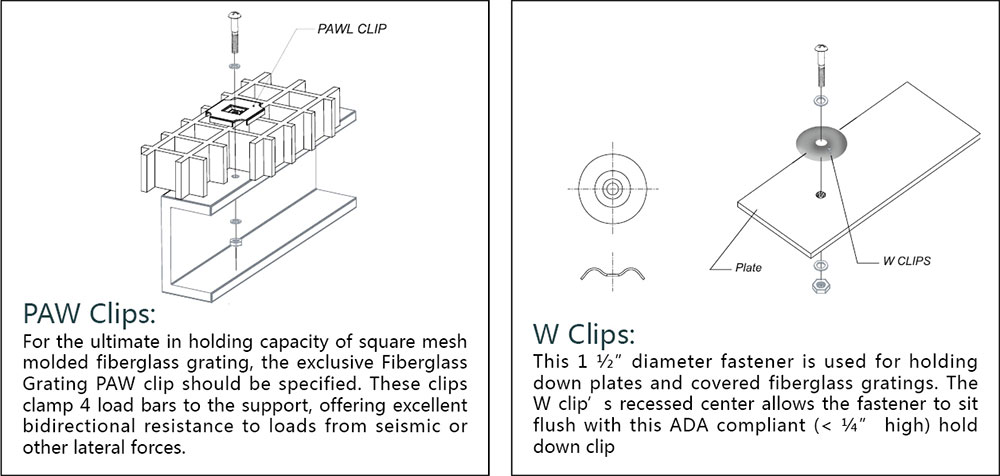

Clips

The clips will help to join gratings together and fasten gratings to support system so as to secure the whole structure. Endura supplies various types of clips for its grating.

When cutting frp Grating , please always wear safety goggles to protect your eyes and a dust mask to reduce dust inhalation. Also wear gloves and a shop coat with neck and sleeves taped to prevent skin irritation. Work in a well-lighted and ventilated area.

Cutting Products

Depending on the amount (lineal feet) of fiberglass grating to be cut, a variety of shop tools can be used. For the best results, use a heavy-duty rotary saw with a masonry, carbide or diamond coated blade. Firm support of the panels will prevent shifting. Turning the panel bottom-side-up gives a smooth surface for the saw to ride on and reduces chipping. Be sure to allow for the blade kerf when measuring.

Grinding

All cut edges should be ground smooth. Use a coarse gritted, open coated (resin) grinding disk.

Finishing

All cut surfaces should be coated with resin to prevent corrosion of glass fibers. A coating of a two-part resin system or comparable to the resin used in the manufacture of the fiberglass grating should be used to maintain corrosion resistance.

Installation

Installation recommendation-whenever possible, provided for a minimum of 1-1/2”(40mm) bearing support at all grating support points. Hold down clips should be used at the rate of one clip for every 6 square feet(0.56square meters) of grating minimum,or at least 4 clips for any square or rectangular piece, or at least 3 for a triangular piece

Clips

The clips will help to join gratings together and fasten gratings to support system so as to secure the whole structure. Endura supplies various types of clips for its grating.