Advantages of FRP Grating Over Steel Grating: Why FRP is Replacing Steel

In industrial applications, choosing the right grating material is crucial for performance, safety, and long-term cost savings. Traditionally, steel grating has been the preferred choice due to its strength and durability. However, with advancements in composite materials, Fiberglass Reinforced Plastic (FRP) grating is rapidly emerging as a superior alternative.

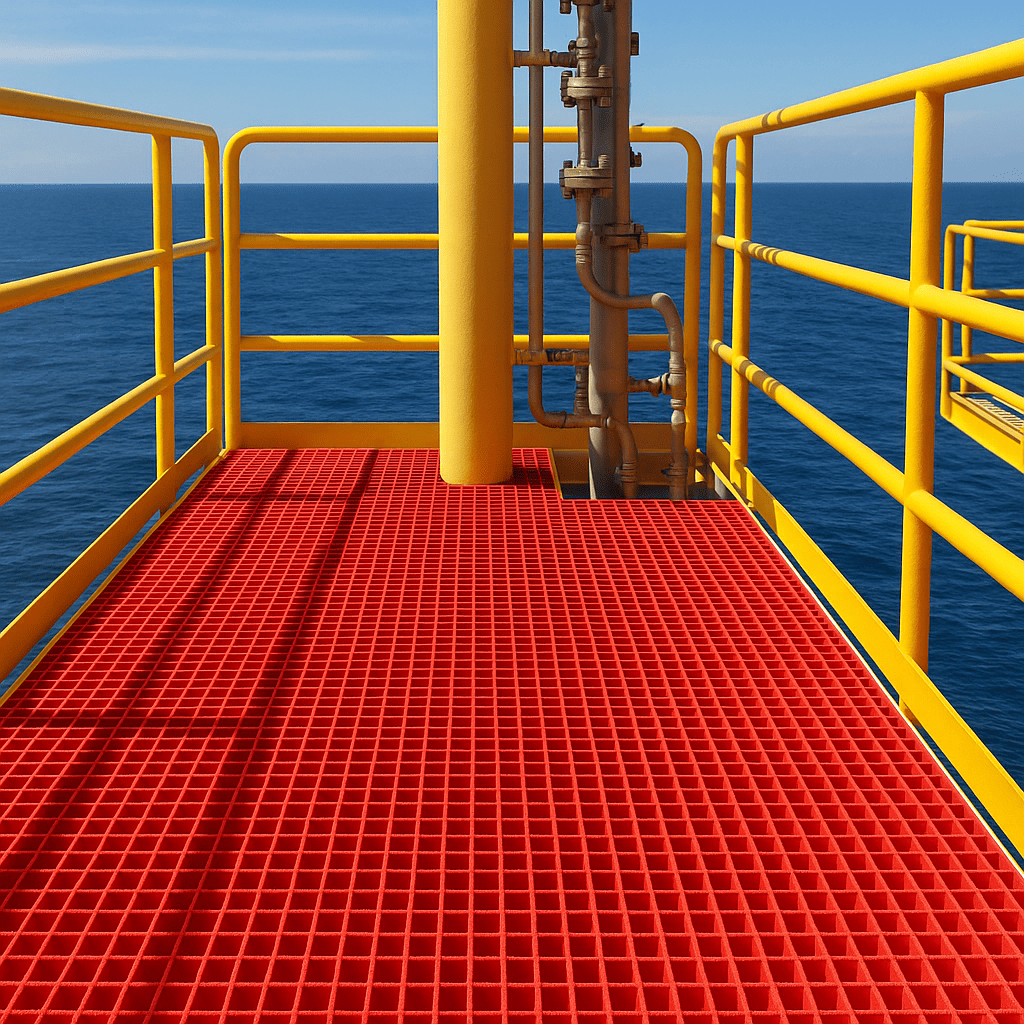

One of the primary advantages of FRP grating is its excellent corrosion resistance. Unlike steel, which can rust and degrade in harsh chemical and marine environments, FRP grating remains unaffected by moisture, chemicals, and UV exposure. This ensures a significantly longer service life with minimal maintenance, reducing the need for costly repairs or replacements.

Additionally, FRP grating is lightweight—approximately one-quarter the weight of steel—making it much easier and safer to handle, transport, and install. This not only lowers labor costs but also reduces the need for heavy lifting equipment and minimizes workplace injuries.

Another key benefit is FRP’s non-conductive nature, which enhances workplace safety in electrical environments. Furthermore, FRP grating offers superior slip resistance with various surface options, making it ideal for areas where safety is a top priority.

From a total cost of ownership perspective, while the initial investment in FRP grating may be comparable to steel, the reduced maintenance, longer lifespan, and improved safety translate into substantial long-term savings.

In summary, FRP grating outperforms steel in corrosion resistance, weight, safety, and lifecycle cost, making it the optimal choice for modern industrial facilities. As industries demand more durable and cost-effective solutions, FRP grating is becoming the new standard, gradually replacing traditional steel grating across a wide range of applications.