What’s FRP? Understanding Fiberglass Reinforced Plastic and Its Industrial Potential

In today’s competitive industrial landscape, material innovation plays a pivotal role in project success, especially in sectors where durability, corrosion resistance, and strength-to-weight ratio are crucial. One material that has garnered widespread attention and adoption is FRP, or Fiberglass Reinforced Plastic. But what exactly is FRP, and why is it increasingly favored across diverse industries?

Defining FRP: Composition and Structure

Fiberglass Reinforced Plastic (FRP) refers to a composite material made by reinforcing a polymer matrix—usually a thermosetting resin such as polyester, vinyl ester, or epoxy—with fine glass fibers. This unique combination merges the tensile strength and flexibility of glass fibers with the resistance and versatility of polymers, resulting in a lightweight, robust, and highly durable material.

The manufacturing process typically involves embedding glass fibers within the polymer matrix, either in continuous or chopped form. This structure gives FRP enhanced structural integrity and allows for significant customization in terms of thickness, shape, and mechanical properties according to project requirements.

Advantages of FRP: Why Choose It?

FRP’s exceptional performance characteristics position it as a superior alternative to traditional materials like steel, aluminum, and wood in many applications. Some of its key advantages include:

- Corrosion Resistance: Unlike metals, FRP does not rust or corrode, making it ideal for harsh or chemically aggressive environments such as chemical processing plants, water treatment facilities, and marine applications.

- High Strength-to-Weight Ratio: FRP materials are significantly lighter than metals but can match or even exceed their mechanical strength, enabling easier transportation, handling, and installation.

- Low Maintenance: The inherent resistance to moisture, chemicals, and UV exposure means FRP structures require less frequent maintenance, resulting in lower life-cycle costs.

- Design Versatility: FRP can be molded into complex shapes and configurations, offering design flexibility unattainable with conventional materials.

Industrial Applications of FRP

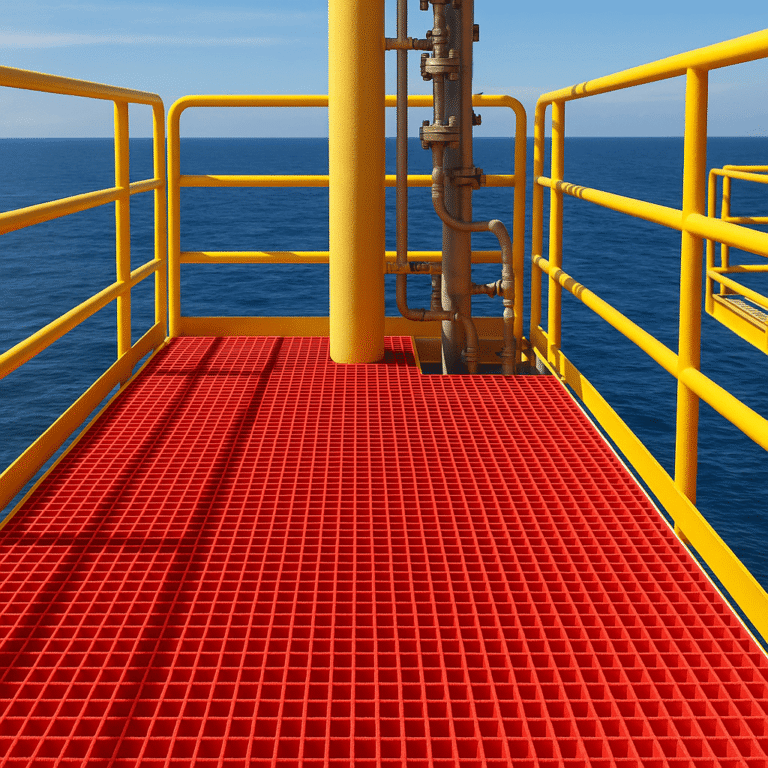

The remarkable properties of FRP have facilitated its widespread adoption across numerous industries. FRP grating, for example, is commonly used in industrial walkways, platforms, trench covers, and stair treads due to its slip resistance and load-carrying capacity. Other applications include structural profiles, piping, cable trays, and even architectural features.

Key sectors utilizing FRP solutions include:

- Chemical processing

- Oil and gas

- Marine and offshore

- Water and wastewater treatment

- Power generation

- Construction and infrastructure

Conclusion

As industries continue to seek materials that balance strength, durability, and cost-effectiveness, FRP is set to become an even more prominent solution. Its unique combination of mechanical and chemical properties positions it as a fundamental material for modern engineering challenges. Whether for retrofitting existing infrastructure or pioneering new construction, FRP provides the innovation and performance required in today’s demanding environments.

Ready to explore how FRP can benefit your next project? Contact us to learn more about our comprehensive FRP solutions.