FRP Molded Grating Production Process

FRP Molded Grating is produced using vertical and horizontal continuous fiberglass that are thoroughly soaked in unsaturated polyester resin. This manufacturing process provides superior bi-directional mechanical properties, ensuring high strength and durability. The mixed materials are placed into an open, heated mold, where the resin and fiberglass cure together to form an integral, grid-like structure.

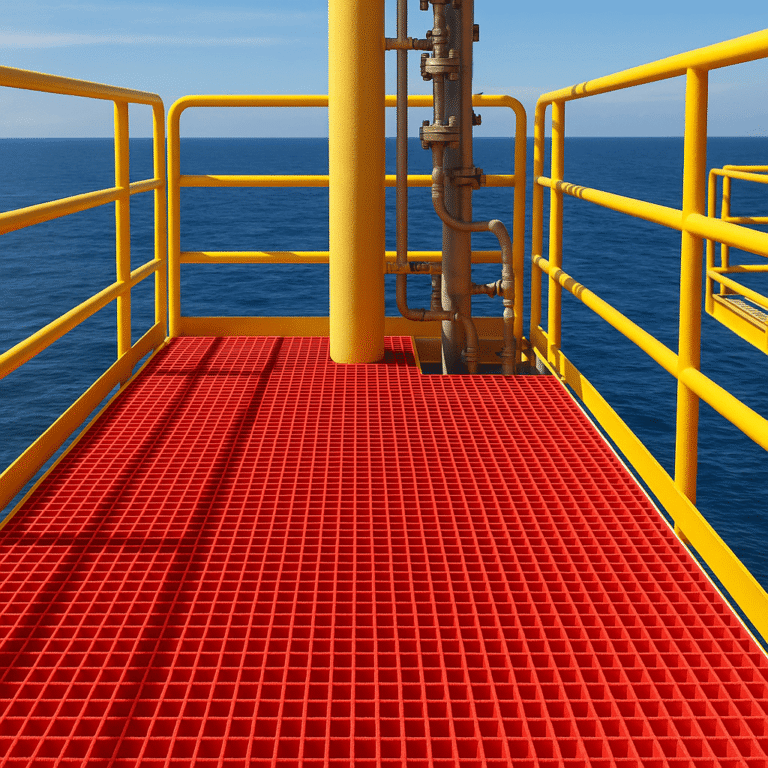

Due to the precise melding of resin and fiberglass, molded FRP gratings exhibit exceptional corrosion resistance, making them ideal for use in even the harshest environments. The gratings are lightweight, easy to cut and install, and require minimal maintenance over their long lifespan. At WEENOOR, we offer a wide selection of panel sizes, colors, and slip-resistant surfaces to meet the diverse needs of our clients. Customization options are available to ensure the ideal solution for any project requirement.