Fiber Bed Mist Eliminator

WEENOOR's fiber bed mist eliminator represents the pinnacle of high-efficiency liquid droplet removal technology for industrial gas streams. Our advanced fiber bed systems utilize specially engineered composite materials arranged in optimized multi-layer configurations to capture and coalesce fine mist particles as small as 0.3 microns. This cutting-edge technology is essential for chemical processing, petrochemical refineries, gas processing plants, and other critical industrial applications where superior mist elimination ensures process efficiency, equipment protection, and environmental compliance.

High-performance FRP fiber bed mist eliminator units for demanding industrial environments

Advanced composite fiber bed elements with optimized multi-layer design for maximum efficiency

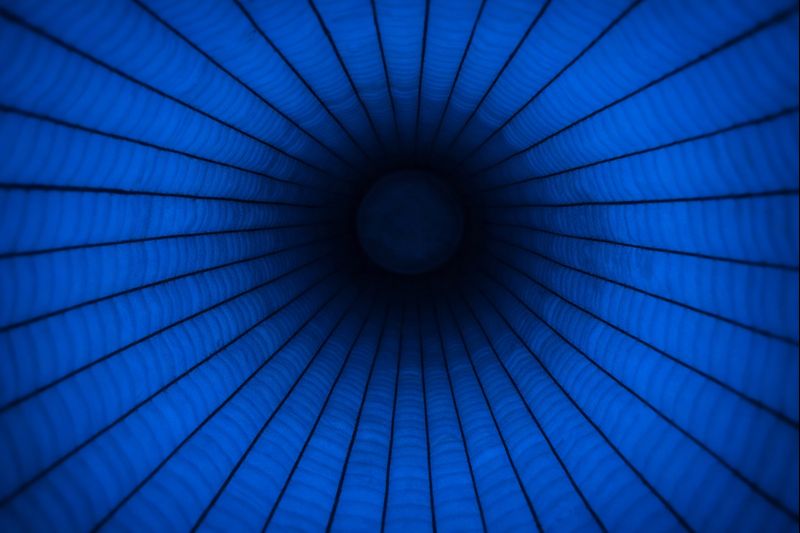

Candle Filter Mist Eliminator Construction

Our Candle Filter Mist Eliminator Construction utilizes advanced vertical filtration technology featuring dual-layer mesh assemblies filled with specially treated compressed fiber materials. These cylindrical filter elements range from 610mm to 6100mm in height, engineered with concentric cage structures or parallel flat screen configurations to optimize mist separation efficiency. The filtration media consists of proprietary compressed glass fiber materials enhanced with specialized treatments, while structural components including inner and outer screens are fabricated from high-grade alloys, engineered thermoplastics, or fiber-reinforced composite materials. Our modular design approach allows for customized configurations tailored to specific process conditions, with mounting flanges and support frameworks available in various weldable metals, advanced polymers, or reinforced resin composites to ensure optimal performance across diverse industrial applications.

Stainless steel alloy screen mesh cage

Glass fiber reinforced plastic cage

WEENOOR's fiber bed mist eliminators are engineered for continuous operation in the most demanding industrial environments. Our systems feature robust FRP construction with superior corrosion resistance, easy maintenance access ports, and extended service life characteristics. The modular design philosophy enables straightforward installation and fiber bed element replacement without requiring complete system shutdown, minimizing operational disruption and maintenance costs.

Fiber Bed Mist Eliminator Cages

Premium fiberglass inner and outer cage solutions for industrial mist elimination systems. Engineered for superior performance and durability.

Product Overview

Our Fiber Bed Mist Eliminator Cages are precision-engineered FRP components designed to support and contain fiber bed media in industrial mist elimination applications. Available in both inner cage and outer cage configurations, these products offer exceptional corrosion resistance, structural integrity, and long-term performance in demanding chemical processing environments.

Fiberglass Inner Cages

Core Support Structure: Provides internal framework for fiber bed media containment

Perforated Design: Optimized hole patterns for maximum flow efficiency

Chemical Resistance: Multi-resin options for aggressive environments

Fiberglass Outer Cages

External Containment: Robust outer shell for complete system protection

Structural Reinforcement: Enhanced load-bearing capacity for large installations

Vessel Integration: Custom mounting solutions for seamless installation

Technical Specifications Available

Get detailed drawings, material specifications, and custom engineering solutions for your mist eliminator project.

Key Performance Features

- Ultra-high efficiency mist removal (up to 99.99%)

- Captures submicron particles down to 0.3 microns

- Ultra-low pressure drop design for energy efficiency

- Superior FRP corrosion resistance for extended service life

- Modular construction for simplified maintenance

- Wide operating temperature and pressure ranges

- Compact space-saving design for installation flexibility

- Self-draining fiber bed prevents liquid accumulation

- Compatible with diverse gas compositions

- Fully customizable sizes and configurations

- Minimal maintenance requirements

- Proven performance in harsh industrial environments

Fiber Bed Mist Eliminator Installation Types

Hanging-style Fiber Bed Mist Eliminator - Also known as Forward Flow, hangs from a tube sheet or vessel divider. This configuration is straightforward to install and maintain. In this design, contaminated gases enter the outside of the element, while clean gases exit the central core.

STANDING STYLE ELEMENTS

HANGING STYLE ELEMENTS