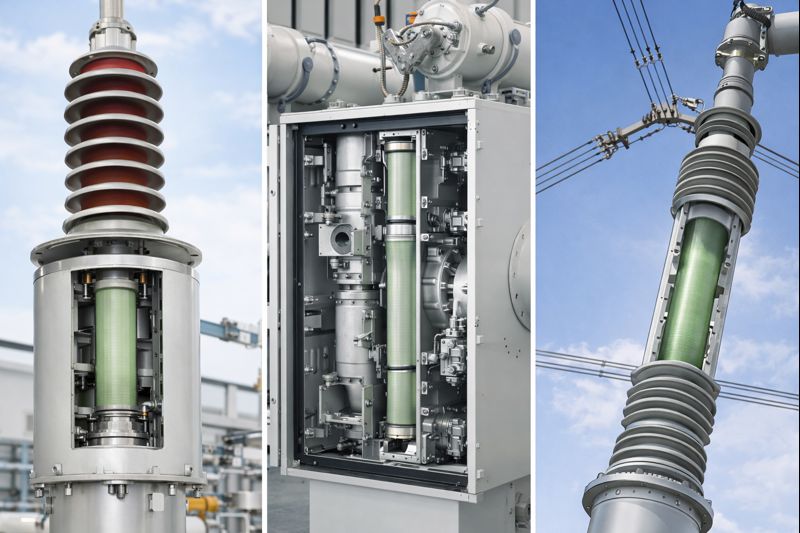

Epoxy Fiberglass Filament Wound Tubes for High Voltage Electrical Insulation

Structural and insulating components designed for high voltage electrical equipment, where mechanical strength, insulation reliability and long-term performance are critical.Widely used in surge arresters, SF₆ switchgear, transformers and composite hollow insulators.

Epoxy Fiberglass Filament Wound Tube

Epoxy fiberglass filament wound tubes are structural and insulating components designed for high voltage electrical equipment. By controlling fiber tension, winding angle and resin impregnation, the tube achieves optimized mechanical strength and reliable electrical insulation performance.

Premium Materials

High-grade epoxy resin systems and continuous glass fiber filaments for superior performance.

Precision Manufacturing

Advanced filament winding technology with controlled fiber orientation and resin impregnation.

Quality Assurance

Rigorous testing and quality control ensuring consistent electrical and mechanical properties.

Why Filament Wound Epoxy Tubes

Designed Fiber Orientation

Fiber orientation is designed according to axial and radial load requirements, providing balanced mechanical strength.

Epoxy Resin System

Epoxy resin system specifically selected for high voltage electrical insulation applications.

Vacuum-Degassed Resin

Vacuum degassing minimizes internal voids and improves dielectric stability.

Long-Term Performance

Stable mechanical and electrical performance under long-term electrical and environmental stress.

Filament Winding Manufacturing Process

Continuous Filament Winding

Continuous filament winding with controlled fiber tension ensures consistent mechanical properties throughout the tube structure.

Optimized Winding Angles

Precisely calculated winding angles for optimal axial and radial strength distribution based on application requirements.

Epoxy Resin Impregnation

Complete epoxy resin impregnation with vacuum degassing eliminates voids and ensures superior dielectric properties.

Controlled Curing Process

Controlled curing and post-curing process ensures complete resin crosslinking and dimensional stability.

Setup & Preparation

Mandrel preparation and fiber routing

Winding Process

Controlled fiber placement and resin application

Curing & Post-Cure

Temperature-controlled curing cycles

Quality Control

Final inspection and testing

Key Properties

Mechanical Properties

- • Good dimensional stability during long-term service.

- • High axial and bending strength suitable for load-bearing structures.

Electrical Properties

- • High dielectric strength and low dielectric loss.

- • Stable insulation behavior under continuous electrical stress.

Thermal Performance

- • Thermal class can be customized according to application requirements, including Class B (130°C), Class F (155°C) and Class H (180°C).

Gas Tightness

- •High density filament wound structure suitable for gas-insulated applications such as SF₆ switchgear and GIS.

Technical Parameters

| Item | Description |

|---|---|

| Material | Epoxy resin with glass fiber reinforcement |

| Outer Diameter | Length less than 11000mm, if φ less than 1100mm |

| Outer Diameter | Length less than 5300mm, if φ less than 650mm |

| Density | 1.8-2.2 g/cm³ |

| Flexural Strength | 100-200 MPa |

| Compressive Strength | >200 MPa |

| Shear Strength | >32 MPa |

| Dielectric Loss Factor | ≤0.02 at 50Hz |

| Dielectric Constant | 4.5-5.5 at 1MHz |

| Volume Resistivity | ≥10¹¹ Ω·m |

| Parallel Laminate Insulation Resistance | ≥10⁹ Ω |

| Perpendicular Laminate Dielectric Strength | ≥15 kV/mm (according to IEC 60243-1) |

| Surface Dielectric Strength | ≥20 kV/mm |

| Insulation Resistance | ≥5x10⁸ Ωm |

Power Transmission Applications

Critical insulation components in high voltage transmission and distribution systems worldwide.

Industrial Installations

Proven performance in demanding industrial environments with extreme operating conditions.

Manufacturing & Customization

Manufactured in one of China's major industrial bases for electrical insulation components, we provide customized filament wound tubes according to drawings and technical requirements.

Advanced Manufacturing

State-of-the-art filament winding equipment and controlled production environment.

Custom Design

Engineering support for custom dimensions, properties, and performance requirements.

Global Shipping

Secure packaging and worldwide shipping with complete export documentation.

Customization Capability

Ready to Discuss Your Insulation Requirements?

Connect with our engineering team for custom solutions, technical consultation, and competitive pricing for your high voltage electrical insulation projects.