FRP/GRP

Pipes & Tubes

Built to Last. Engineered to Perform

Durable, corrosion-resistant and highly efficient, WEENOOR FRP pipes combine cutting-edge filament winding technology with decades of expertise.

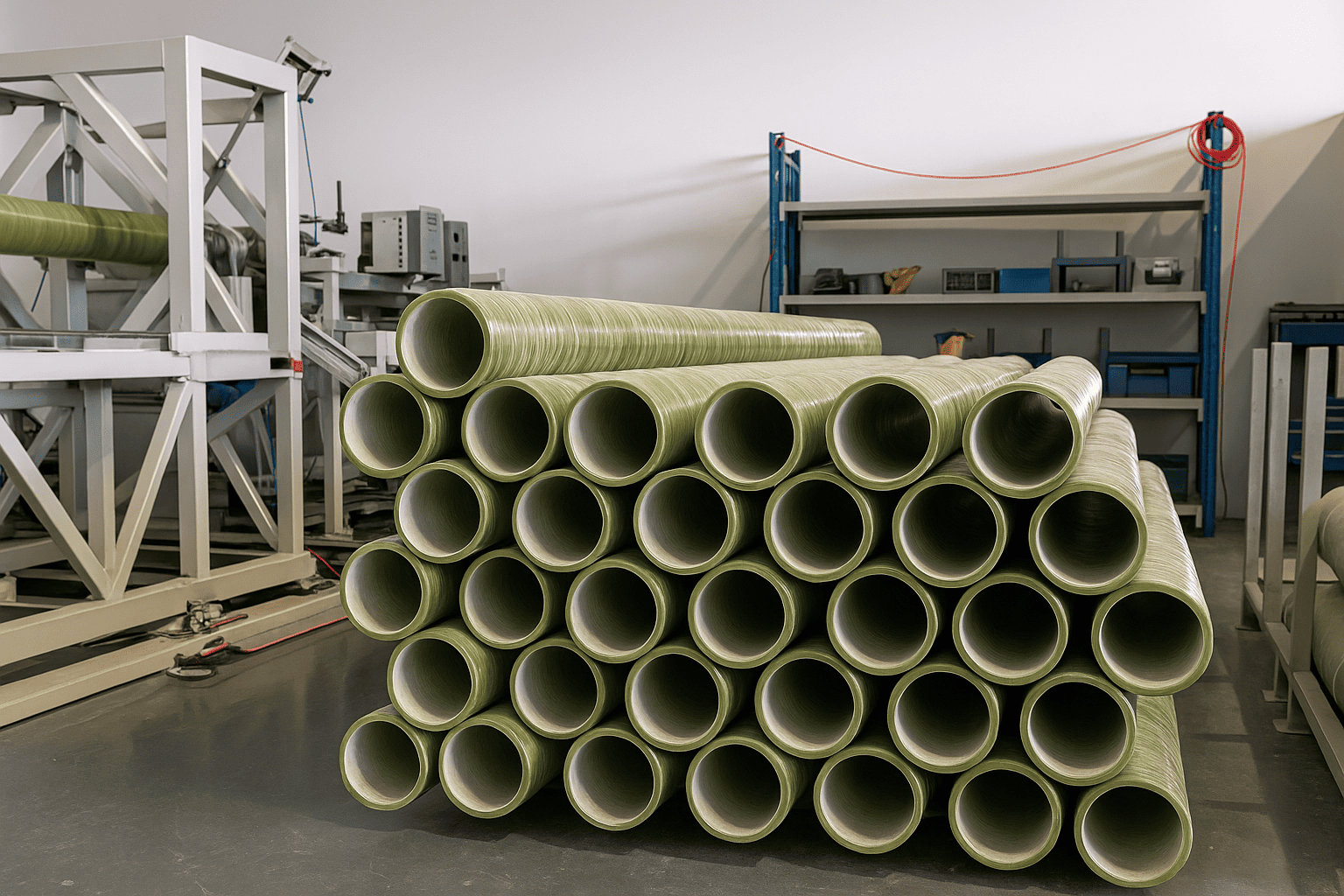

WEENOOR Fiberglass Filament Wound Pipes

WEENOOR manufactures high-quality Fiberglass Reinforced Plastic (FRP) and Glass Reinforced Plastic (GRP) pipes using advanced filament winding technology. Our FRP piping systems are renowned worldwide for excellent mechanical properties, superior corrosion resistance, and lightweight construction. The complete system includes a full range of fittings including elbows, tees, reducers, flanges, couplings, and custom components designed to meet the most demanding industrial applications.

Key Features

- Superior Corrosion & Chemical Resistance: Engineered for harsh industrial environments

- High Strength-to-Weight Ratio: Exceptional durability with easy handling and installation

- Low Maintenance Requirements: Resistant to rust, scaling, biological growth, and chemical degradation

- Extended Service Life: Designed for decades of reliable performance in demanding conditions

- Multi-Resin Options: Available in polyester, epoxy, and phenolic resin systems

Industrial Applications

- Water Treatment & Distribution: Potable water, fire protection, and filtration systems

- Chemical Processing: Aggressive chemical transport and process piping applications

- Oil & Gas Industry: Petroleum product transport, crude oil pipelines, and gas distribution

- Sewage & Wastewater: Treatment plants, drainage systems, and municipal infrastructure

- Power Generation: Cooling water systems, desalination plants, and industrial utilities

- Marine & Offshore: Seawater applications and corrosive marine environments

Why Choose WEENOOR?

- Proven Global Reliability: Serving 30+ countries with consistent quality and performance

- Custom Engineering Solutions: Tailored designs to meet specific project requirements

- Rapid Response Service: 24-hour quotations and fast sampling (≤7 days)

- Flexible Order Quantities: Low MOQ policy supporting projects of all sizes

- Complete Technical Support: From design consultation to installation guidance

>

>

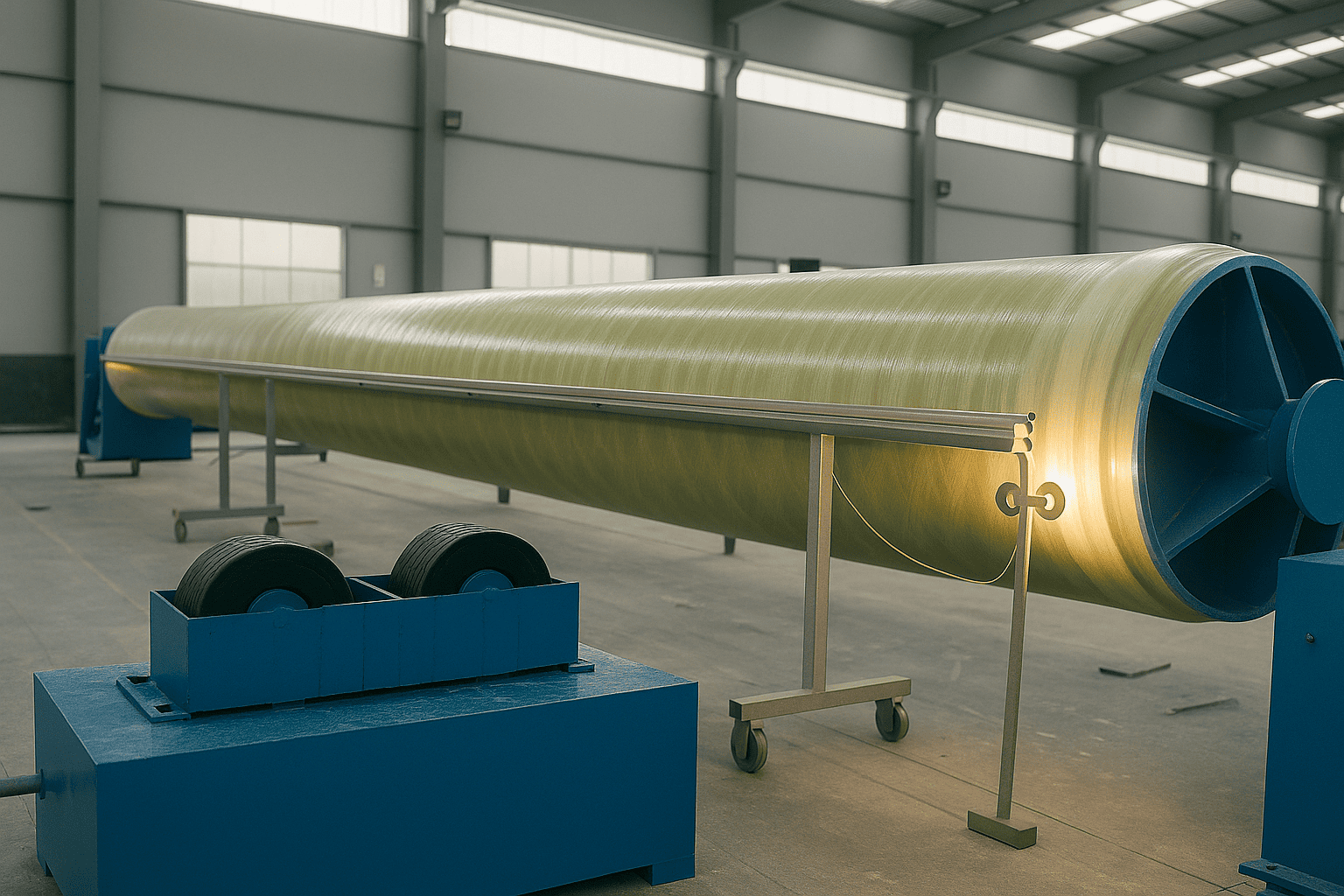

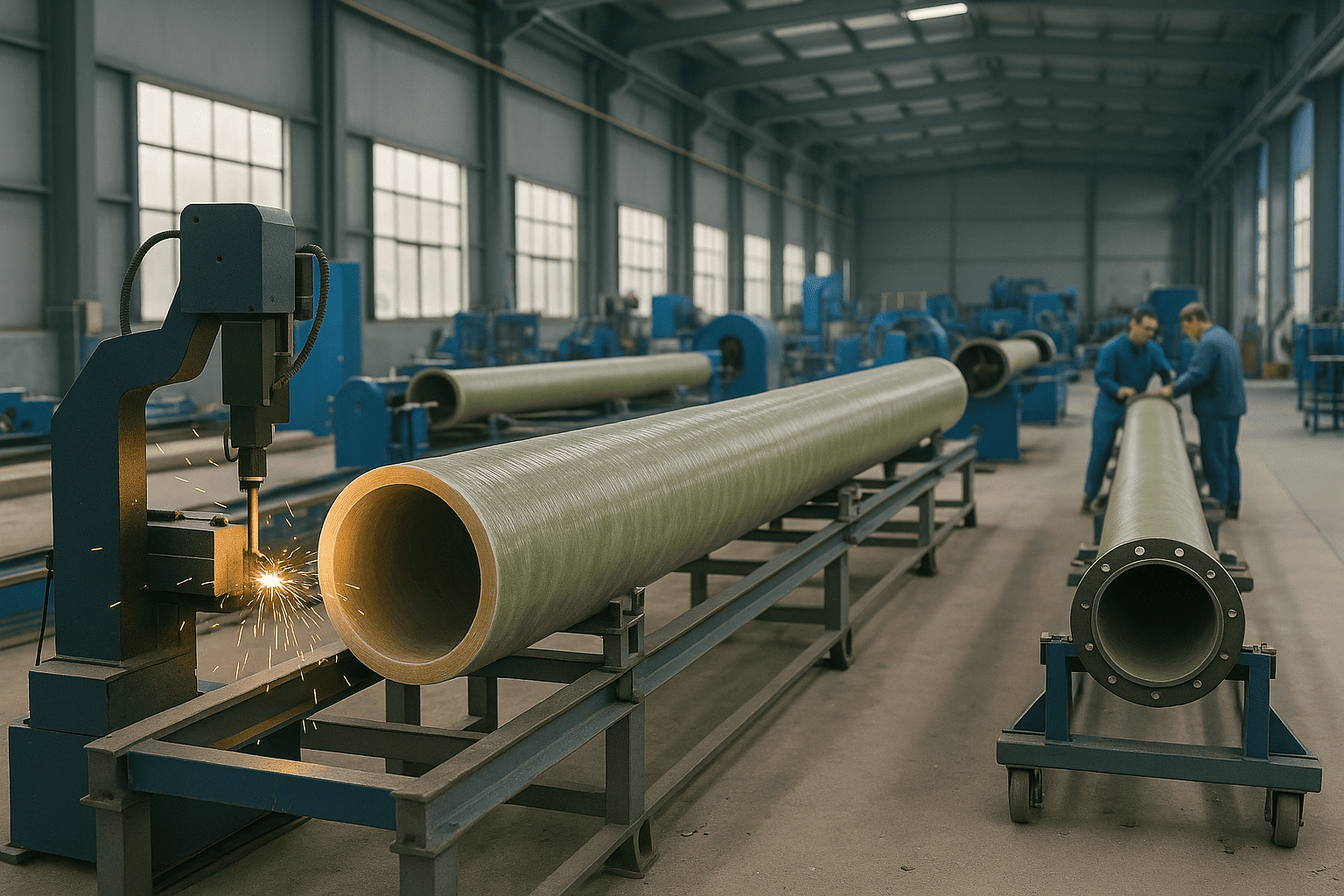

Manufacturing Excellence

Located in Nantong, China's largest FRP manufacturing cluster, WEENOOR utilizes state-of-the-art facilities and advanced technology with rigorous quality control systems.

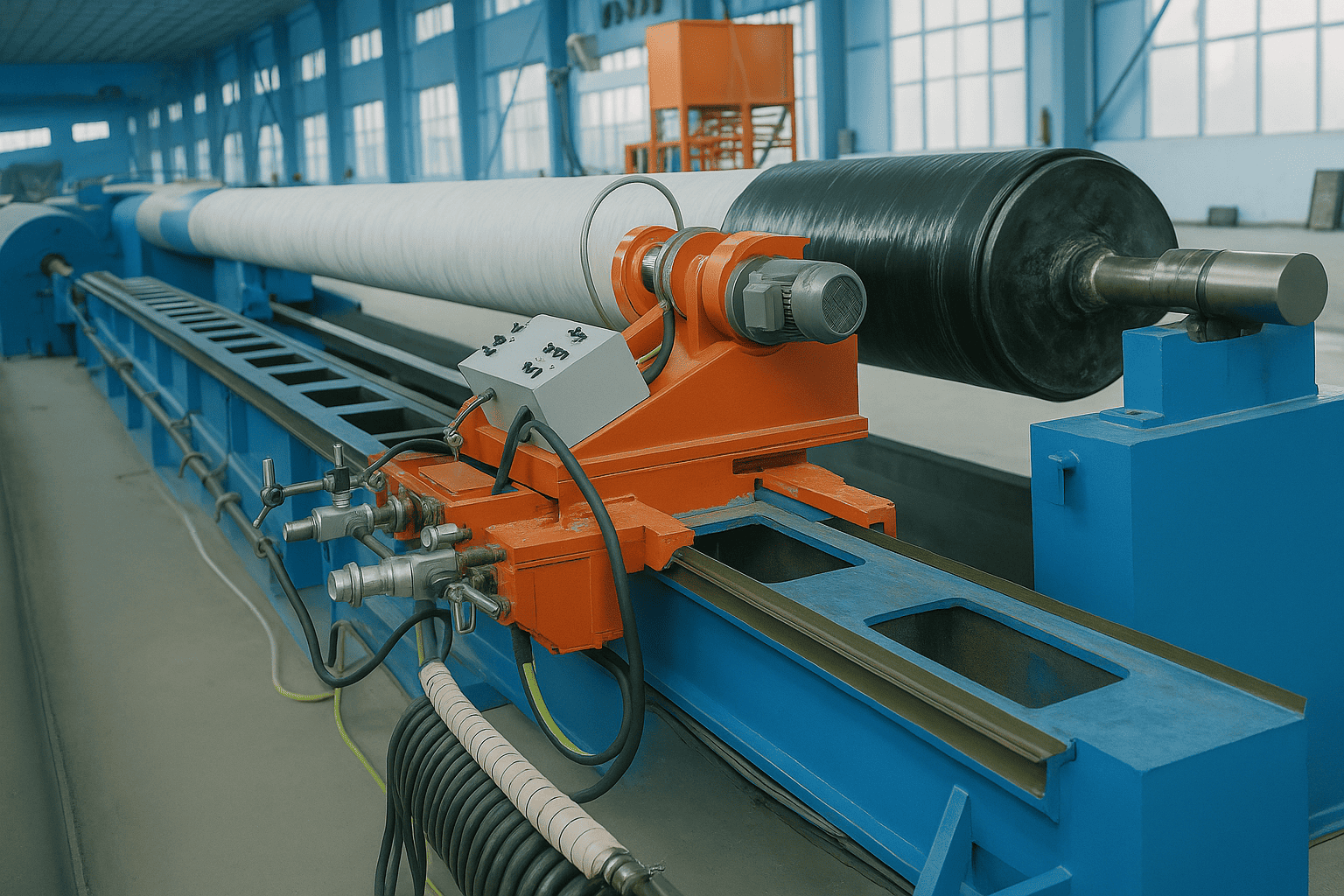

Filament Winding Technology

Automated filament winding systems ensuring precise fiber placement and consistent wall thickness.

Advanced Curing Systems

Precision temperature control ensuring optimal resin curing and maximum mechanical properties.

CNC Machining Centers

Computer-controlled precision cutting and machining for exact dimensions and custom fittings.

Automated Production

Efficient production lines with digital management ensuring quality at every manufacturing stage.

Quality Control & Testing Equipment

Our comprehensive testing facilities ensure every product meets international standards including ASTM, EN, and ISO specifications.

Hydrostatic Testing

High-pressure testing chambers verifying pipe integrity and pressure ratings to design specifications.

Material Analysis Lab

Advanced laboratory for resin content analysis, fiber orientation testing, and material composition verification.

Mechanical Testing

Universal testing machines for tensile, compression, and flexural strength measurements.

Dimensional Inspection

Precision measuring instruments including CMM systems for accurate dimensional verification.

Chemical Resistance Testing

Specialized testing for pipe performance in various chemical environments and temperatures.

International Certifications

ISO 9001 certified processes with full traceability and documentation for every product batch.

WEENOOR FRP pipes combine advanced continuous filament winding technology with premium materials to deliver durable, corrosion-resistant solutions for water, wastewater, chemical, and industrial applications. From desalination plants to chemical processing facilities, WEENOOR offers proven reliability and long-term performance for the most demanding environments worldwide.

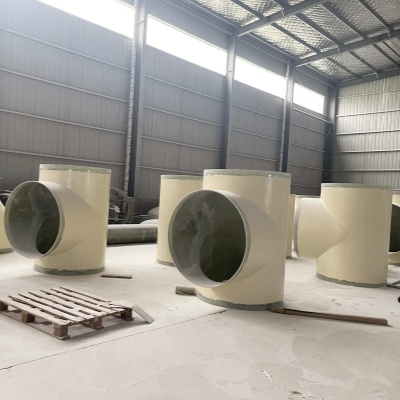

FRP PIPES & TUBES

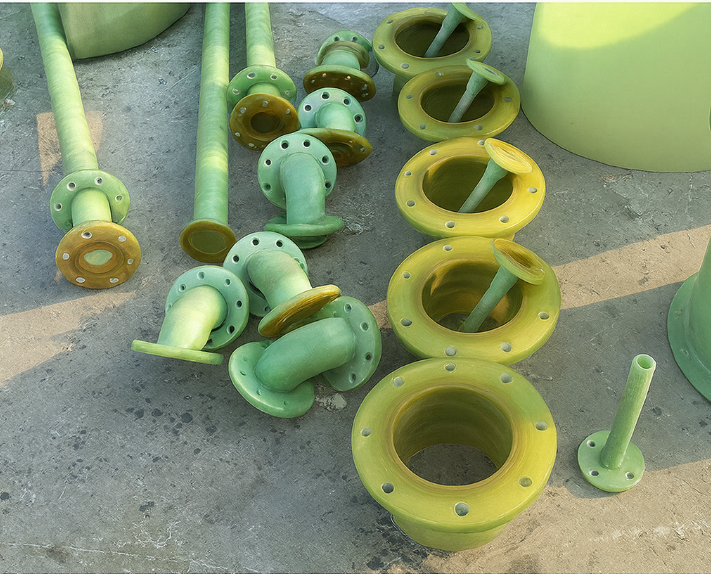

FITTINGS & ACCESSORIES

WEENOOR FRP fittings are designed to deliver reliable, watertight connections for all pipe joint systems. Manufactured using the same advanced technology as our pipes, they ensure perfect fit, strength, and long-term performance in demanding industrial environments.

Ready for Your FRP Pipe Project?

Connect with our engineering team for custom FRP pipe solutions, technical consultation, free samples, and competitive pricing.

24-hour quotations • Free samples • Low MOQ • Global shipping