Heavy-Duty FRP Pultruded Grating

Industrial-strength composite gratings engineered for extreme loads, chemical resistance, and long-term durability. Built for industrial platforms, walkways & heavy machinery.

Why Choose Pultruded FRP Grating?

Engineered for industrial applications where steel fails. Superior strength-to-weight ratio with unmatched chemical resistance.

Steel Grating Issues

- Corrosion & rust problems

- Heavy weight increases costs

- Requires frequent maintenance

- Electrical conductivity risks

FRP Pultruded Grating

- 100% corrosion resistant

- 40% lighter than steel

- Maintenance-free operation

- Electrical insulation safety

Aluminum Grating

- Limited chemical resistance

- Lower strength than FRP

- Higher material costs

- Thermal expansion issues

Technical Specifications

Premium FRP Pultruded Gratings

High-performance I-Bar and T-Bar pultruded FRP gratings engineered for superior strength, corrosion resistance, and long-term durability in demanding industrial environments.

WEENOOR® I-Bar Stair Treads

Fiberglass Grating Stair Tread Panel, I-Bar Profile, Polyester Resin, Grey, 38mm Height x 15mm Top Flange Width I-Bar, Medium Grit Anti-Slip Surface, 50mm Wide Integral Nosing on One Side, 60% Open Area. Engineered for safe pedestrian access with enhanced slip resistance and drainage.

Item Code: WN-I-ST-6015

Standard Sizes: 280mm x 3660mm, 305mm x 4000mm

Load Rating: 2.4 kN/m² (245 kg/m²)

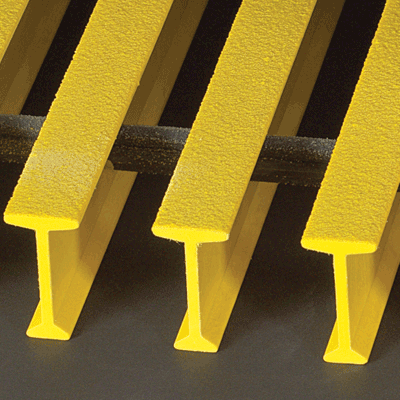

WEENOOR® T-Bar Heavy Duty Grating

Heavy Duty Pultruded Fiberglass Grating, T-Bar Profile, Vinyl Ester Resin, Safety Yellow, 65mm Height x 32mm Top Flange Width T-Bar, Coarse Grit Surface, Reinforced Cross-Rods, 45% Open Area. Maximum strength solution for extreme load applications, equipment platforms, and structural decking.

Item Code: WN-T-HD-4532

Standard Sizes: 1220mm x 3660mm, 1525mm x 3050mm

Load Rating: 7.2 kN/m² (734 kg/m²)

FRP Pultruded Grating Specifications

Complete dimensional and performance data for our I-Bar pultruded FRP grating series

| Type | Height Inch (mm) |

Top edge width (mm) |

Space between (mm) |

Clearance width (mm) |

Open area ( % ) |

Estimated weight Kg/m² |

|---|---|---|---|---|---|---|

| I-4010 | 25 | 15 | 25 | 10 | 40 | 17.8 |

| I-5010 | 25 | 15 | 30 | 15 | 50 | 15.1 |

| I-6010A | 25 | 15 | 38 | 23 | 60 | 12.2 |

| I-6010B | 25 | 8 | 19.8 | 11.8 | 60 | 13.7 |

| I-4015 | 38 | 15 | 25 | 10 | 40 | 22 |

| I-5015 | 38 | 15 | 30 | 15 | 50 | 19.1 |

| I-6015 | 38 | 15 | 38 | 23 | 60 | 16.2 |

| I-4012 | 30 | 15 | 25 | 10 | 40 | 19.1 |

| I-5012 | 30 | 15 | 30 | 15 | 50 | 16.1 |

| I-6012 | 30 | 15 | 38 | 23 | 60 | 13.1 |

| I-40125 | 32 | 15 | 25 | 10 | 40 | 19.8 |

| I-50125 | 32 | 15 | 30 | 15 | 50 | 17.4 |

| I-60125 | 32 | 15 | 38 | 23 | 60 | 13.5 |

| I-4020 | 50 | 15 | 25 | 10 | 40 | 28.5 |

| I-5020 | 50 | 15 | 30 | 15 | 50 | 24.2 |

Load Capacity

All specifications tested according to ASTM E84 and EN standards for industrial applications

Custom Sizes

Non-standard dimensions and special profiles available upon request with engineering support

Resin Options

Available in polyester, epoxy, and phenolic resins for different environmental conditions

Need Custom FRP Grating Solutions?

Contact our engineering team for detailed specifications, load calculations, and customized quotations for your specific project requirements.

FRP Pultruded Grating Applications

High-strength, corrosion-resistant pultruded gratings for industrial platforms, walkways, and structural applications worldwide.

Industrial Platforms

Heavy-duty pultruded gratings for chemical plants, oil refineries, and manufacturing facilities requiring superior load capacity and chemical resistance.

Marine Walkways

Corrosion-proof pultruded gratings for offshore platforms, docks, and marine infrastructure with excellent slip resistance and durability.

Bridge Decking

Lightweight yet strong pultruded gratings for pedestrian bridges, access bridges, and structural decking with long-term reliability.

Ready to Upgrade to FRP?

Join thousands of satisfied customers worldwide who've made the switch from steel to high-performance FRP grating. Get your project started today.

🚀 24-hour response guaranteed

📦 Free samples within 7 days

🌍 Shipping to 30+ countries